The Introductory Physics Laboratory (IPL for short) in the College of Science is one of the biggest teaching labs at Northeastern, serving about 1,300 students every term. It is supervised by professors Baris Altunkaynak, Oleg Batishchev and Paul Champion. Ron Zettlemoyer and Austin Beaudette are the electronics and instructional lab support technicians.

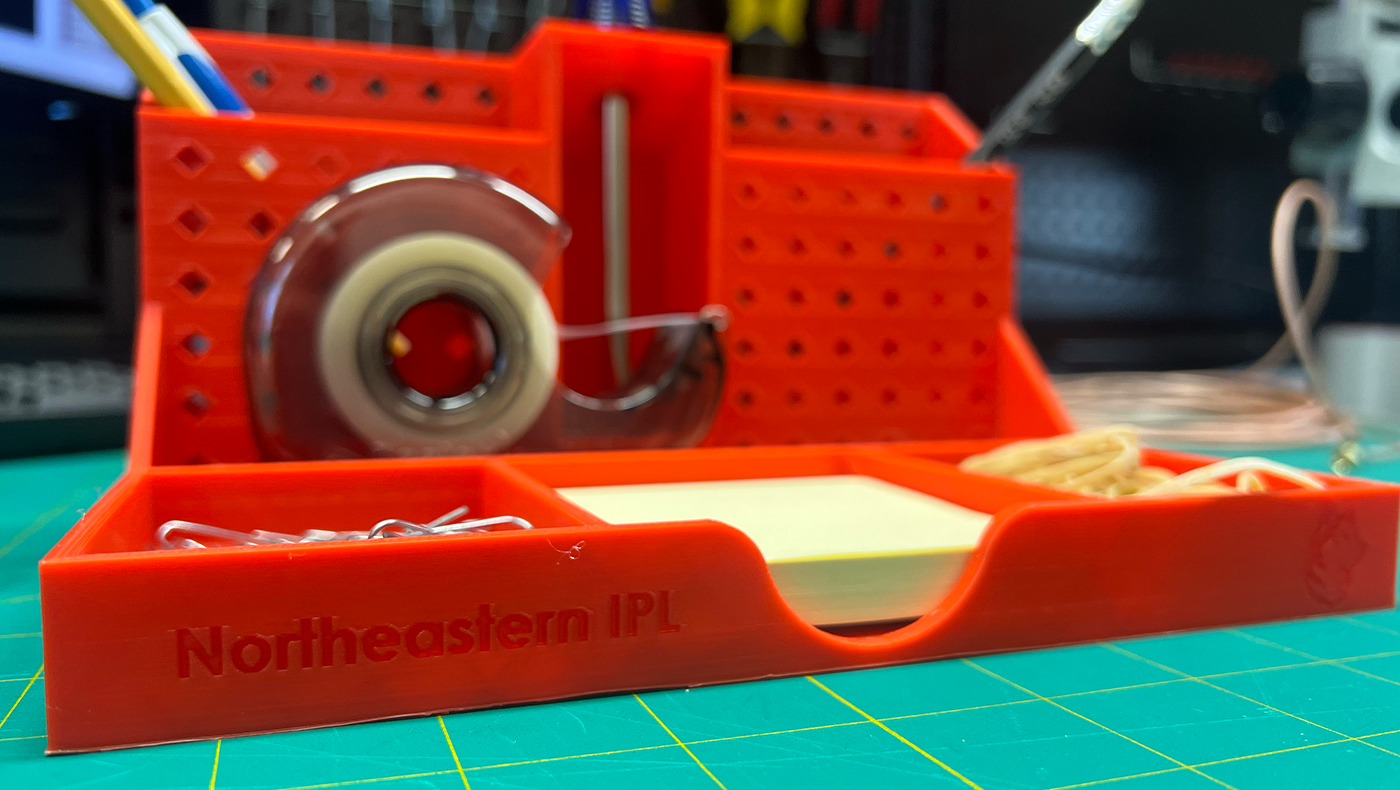

There is a new makerspace, sponsored by the College of Science, in the back of the IPL office, where innovation takes place. Austin, who started working in the IPL two years ago with no 3D printing experience, quickly acquired the skills, and has been helping the team to design in SolidWorks and build innovative lab equipment with 3D printed parts.

The team’s latest innovation is an improved version of an experiment on standing waves. It used to be run with water. Students would change the level of water in a vertical tube throughout the experiment to alter the length of the air column in the tube. However, the water would frequently leak and cause large spills, which was dangerous for people and the equipment. Tuning forks were used to excite the air in the tubes, but they would easily break.

The team decided to rework the experiment to avoid using water and tuning forks.

The innovative design they came up with has a 3D printed plug and slider, 3D printed legs, and a speaker in a 3D printed box. The plug in the tube can be moved from outside with the slider thanks to the embedded Neodymium magnets in both. The speaker is placed at one end of the tube and emits a constant tone. The plug serves as a barrier for the sound waves, replacing the water, and runs along the tube so students can easily adjust where the sound bounces off.

When the slider is placed at the correct position, a resonance is formed, and it makes a loud sound. Students use this information to determine the speed of sound.

Converting the equipment to this setup not only eliminates the mess, but it also allows students to focus on learning instead of spending a lot of time adjusting the apparatus that required two people. The new equipment is so precise that one can use it to determine the difference in the speed of sound on a cold and a hot day.

Austin designed all 3D parts in SolidWorks and the Printed Circuit Board (PCB) for the speakers using KiCad. He also designed a tone generator applet for lab PC to drive the speakers.

[There are 3 printers available in the workshop. Two use PLA, the more commonly used filament material, and one can also print with ABS which is stronger but requires a higher temperature.]

The old standing waves setup was bulky. Due to the limited storage space, the IPL had only a few setups per class that had to be shared by many groups of students. The IPL team designed, and the NU Carpentry shop built a compact cart to hold enough equipment to run 10 sections with 5 groups each of the same experiment in parallel. About 800 Northeastern students will perform this experiment in the Fall semester alone, so it is a big improvement to the educational process by IPL.

This isn’t the only innovation here. Last year, the IPL team upgraded their 30-year-old air table experiments that used spark timers to mark the position of metal pucks as they move on large sheets of paper. Students now use the IPL Tracker, a modern live webcam tracking software that Prof. Altunkaynak developed for acquiring the data. Once again, students are now able to focus on physics and data analysis instead of wasting time on a time-consuming process of digitizing by hands paper marks with no pedagogical benefits.

[During this upgrade, 3D printing came to the rescue again. The glass tables had legs that were breaking due to age and poor design. Leveling the tables is very important to this experiment, so Austin designed new adjustable legs and clamps, and printed 150 sets. This saved valuable lab time that was previously spent leveling the tables.]

The team comes up with new innovative ideas every day. The only limit is of course their imagination and the time to 3D print parts required in large numbers.

Go behind-the-scenes and take a look at the Introductory Physics Lab!