by Angela Herring

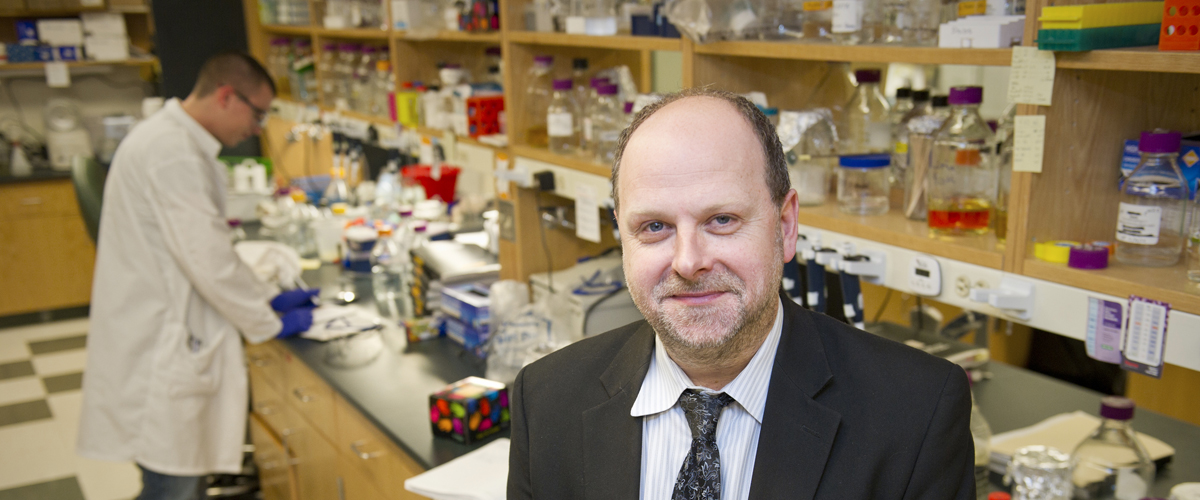

Most organic synthesis processes, which give us everything from small molecule drugs to fossil fuel replacements, require large volumes of hazardous solvents, produce toxic byproducts, and are extremely costly both in time and money. “The goal is to make things faster, cheaper, cleaner,” said Graham Jones, professor and chair of Northeastern’s Department of Chemistry and Chemical Biology, who is helping to push the field of chemistry into greener pastures.

Northeastern is one of 20 universities in the country that have joined forces to commit to a greener way of doing and teaching chemistry. The group will work on developing best practices in the field as well as curricula for both chemistry majors and non-majors alike. For a truly green chemical industry, we must educate not just future chemists but also non-chemist consumers, policy makers, and citizens.

In his own research, Jones is already pushing the green envelope. His team is pioneering a set of new synthetic procedures using both microwave and so-called “lab-on-a-chip” technologies to minimize the environmental and financial impact of producing imaging agents for cancers and central nervous system disorders. “The trick,” he said, “is finding drugs with fluorine in them.”

That’s because he can exchange the benign fluorine with a radioactive isotope, making the drugs visible in PET scanners. Since they are inherently designed to bind to specific cancer or damaged central nervous system cells, they will spontaneously localize around a tumor or area of CNS damage. But the real novelty in Jones’ imaging drugs isn’t what they do, but how they are made.

Instead of a lab bench covered with beakers and test tubes, Jones’ team does its syntheses in miniature microfluidic devices the size of a credit card. Because of the microscopic volumes, the chemistry is fundamentally different than it is on the macro-scale. For instance, it requires a fraction of the volume of solvent normally used in the same reactions and produces considerably fewer byproducts. Because there are fewer byproducts, less post-processing is required to purify the desired compounds.

The lab-on-a-chip takes care of the “cheaper” and “cleaner” variables in Jones’ green equation, but what about faster? To achieve considerably greater reaction speeds, the researchers flow the reaction mixture out of the microfluidic device and into a microwave reactor where it gets a rapid burst of energy. A reaction that normally takes hours now takes minutes or seconds, Jones explained. Additionally, the lab-on-a-chip industry has begun to stack the devices into parallel processing units, allowing for increased scale-up potential.

Jones’ approach reflects a growing movement toward green chemistry, wherein research and industry practices alike adopt methods that are good for the environment and also “keep green in the wallet,” he said. Other approaches include using catalysts to speed up reactions and developing strategies to reduce the number of steps, volume of solvent, and wasted reagents.

One day, Jones said, green chemistry will no longer be a novelty but the norm.